Every chiller is designed with certain delta t and chilled water flowrate values. If the difference between supply and return chilled water line temperatures are lower than the designed chiller delta t then the condition is called low delta T syndrome. It's called a syndrome because of its ill effects on the chiller system. The below example will give a fair understanding of what exactly is the low delta t syndrome in the chiller systems. Generally, in most cases, older chilled water systems are of constant flow type, because of their simple configuration, low capital cost, and easy to operate features.

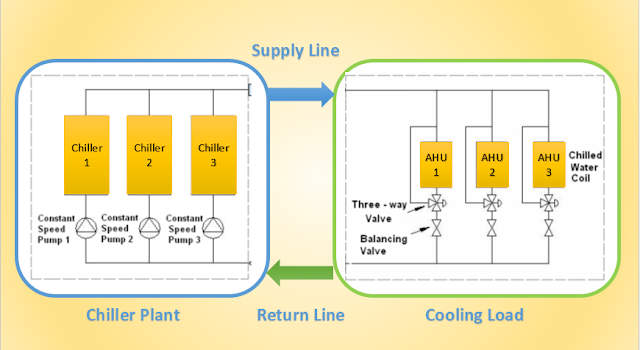

Typical Constant Flow System:

Here in this kind of system, a set of fixed speed pumps caters to the chilled water flow through the entire loop. AHU's catering to the cooling needs will have a 3-way valve placed which can bypass the amount of chilled water at any time based on the load variation, Since the flow is kept always constant and temperature only is varied, these systems are called constant speed systems.

Chiller capacity is generally expressed in terms of Btu/hr which in turn depends on flow and temperature difference across.

Chiller Capacity (Btu/hr) = Flow Through Chiller Evaporator System in GPM X 500 X Chiller Delta T

In these systems, the flow rate is designed to maximum peak condition and is constant. Only the temperature difference between the supply chilled water line and the return water line changes with the change in load. Generally only 1% in a lifetime, chiller systems operate at their design point and rest other times at low load conditions. Due to this always 3 way valves will bypass some or other chilled water flow from respective AHU's and mix it with the return water line to keep the flow constant. Due to this mixing, the return chilled water line temperature comes down and the difference between the supply line and return line (DeltaT) also decreases. Due to constant flow and decreased delta T, chiller capacity will get decreased even at maximum flow conditions. This phenomenon is termed as low Delta T Syndrome,

For example:

Let's consider the designed delta T of the chiller as 12 Degree F = 57(Return Water) - 45 (Chilled Water)

Now suppose due to low loading requirements all the three ahu units have bypassed some amount of chilled water then it gets mixed with a return line and this mixing lowers the temperature of return water line say from 57 Degrees F to 54 Degrees F, then the capacity of chiller gets degraded to

= ((54 - 45) / (57 - 45) ) X 100 = 75%

This means, not only the delivered capacity of the chillers is reduced, but also the operation becomes inefficient as the chillers must remain ON to satisfy the load. This increases the plant’s energy usage and compounding the problem when chillers are not optimally loaded, these are less efficient consuming higher energy rates per ton of cooling (i.e., kW/TR). The system may be keeping the building cool but it is inefficient and a lot of chiller capacity will get wasted.

This is just one example of a cause of Low Delta Syndrome and apart from this, there are several other reasons for this to occur wherein few can be mitigated and few cannot. Below are a few causes of Low Delta T syndrome & measures to overcome them;

Cause 1: Use of 3-way Valves: As explained in the above example these will satisfy the low loading cooling requirements through bypassing the required amount of chilled water to the return line, But the Delta T is getting affected at the Chiller end.

Measure: Use a 2-way valve instead of a 3-way valve and install VFD on the chilled water pumps. As far as performance or requirement at the cooling coil in AHU is concerned, both two way and three-way valves are similar. But three-way valves affects temperature difference by maintaining constant flow whereas 2-way modulating valves operate with the variable flow by giving feedback to VFD's and maintains designed Delta T across chillers, Initial cost of modification will be there but actually avoids severe effects of Low Delta T syndrome and saves enormous amounts of operating costs.

Cause 2: Improper Selection of Coils & Poor Setpoint Controls: Due to improper selection of valves, cooling coil there creates a problem of mismatch with setpoints. For an efficient heat transfer to occur the flow should be as per design value. Even if more flow is allowed than the design, effective heat transfer reduces and decreases return water temperature. Suppose due to complaints from the occupants, the operator might have decreased the AHU setpoint than the design one. Then the modulating valve opens much and allows more flow to happen in the coil. And due to improper selection of coil more flow leads to less heat transfer and outlet coil water temperature reduces. This again causes Low Delta Syndrome.

Measure: Check set points and recalibrate controls regularly. Low setpoints mean the control valves are wide open to allow more flow. The problem of exceeding design flow rates when valves are wide open can be resolved by installing “pressure independent delta-P control valves” that maintains a preset maximum flow regardless of the differential pressure across them (within certain limits). In recent days these pressure independent valves are available in the market with the trade name Energy Valves. And the most important measure is to digitally lock the set point in the AHU controller which actually avoids this issue to a large extent. Also always select the cooling coil designed Delta T value 2 Degree higher than that of chiller designed Delta T.

Cause 3: Wrong selection of two-way valves: An improperly sized two-way control valve may require more chilled water flow when open than the design calls for. With full flow through the coil, even at partial loads, the Delta-T will invariably be lower than design. Also, the oversized or worn two-way valves may act as three-way valves which can lead to “hunting”. (valves alternately open and close causing over and under-shooting of the setpoint). This results in very unstable operation.

Measure: Select the control valves considering the pressure drop of the load served and the available differential across the supply and return mains. Manufacturers usually recommend that wide-open control valve pressure drop shall be equal to or greater than the pressure drop of the coil plus the pipe and fittings connecting them to supply and return mains

Cause 4: Reduction in Coil Effectiveness: Many times due to ageing, waterside fouling, airside dirt clogging effectiveness of coil gets reduced. And the reduction in coil effectiveness increases the flow rate of water required to deliver the desired leaving water temperature, thus giving rise to low delta t syndrome.

Measure: Proper and periodic water treatment and filter cleanliness checks have to be done. Since the chilled water system operates in a closed-loop, the issue with water fouling will be relatively less than that of the issue of dirt accumulation on the airside. This demands for more regular cleaning of airside filters than coil side water treatment

I agree with a lot of the points you made in this article. If you are looking for the 316 Stainless Steel Pipe, then visit Oshwin Overseas. I appreciate the work you have put into this and hope you continue writing on this subject.

ReplyDeleteI found your blog on Google and read a few of your other posts. I just added you to my Google News Reader. You can also visit 304 Stainless Steel Sheet for more Great steel & metals related information and knowledge, Keep up the great work Look forward to reading more from you in the future.

ReplyDeleteHow about the if the condenser is low delta t. what is the points to evaluate. Once your delta t is out of the envelope range it will effect the system performance. The condenser approach what will happen.can you please elaborate which solution to provide.

ReplyDeleteBecause most of the time in the ship condenser delta t is to close. sometimes 2 to 3'c delta t in condenser.

But chiller capacity unload all the time even temperature of chilled water is above the set point already.almost all also in the rig most of the time the promblem is low delta t in the condenser side.

Low Delta T Syndrome in Chiller Systems can significantly impact efficiency and increase energy costs. Proper system design and high-quality materials, such as stainless steel pipes, play a crucial role in maintaining optimal chilled water flow and preventing efficiency losses. Thanks for sharing this insightful post!"

ReplyDelete