Cooling towers are the least maintained utility in industries. Of course, the cooling tower energy consumption is relatively less compared to other utilities but the indirect impact on energy consumption of other systems (Chillers) connected to the cooling tower will be high stressing the need for cooling tower efficiency assessment and improving the same. Below is the list of Ideas to Improve Cooling Tower Energy Efficiency

- Control cooling tower fan based on leaving water temperatures.

- Control to the optimum water temperature as determined from cooling tower and chiller performance data to reduce cooling tower energy consumption.

- Install 2 speed or variable-frequency drives for cooling tower fan control if the number of fans is low else use on-off control if the number of fans is many.

- Turn off unnecessary cooling tower fans when loads are reduced / process is running under partial load

- Replace cooling tower aluminium fan blades with high efficient fibre reinforced plastic (FRP) blades.

- Replace belt driven or gear driven cooling tower fan with direct driven fan or EC Fan.

- Clean clogged cooling tower water distribution nozzles at regular planned intervals.

- Install new nozzles to obtain a more-uniform water pattern which enhances heat transfer.

- Replace splash bars with self-extinguishing PVC cellular-film fill.

- On old counterflow cooling towers, replace old spray-type nozzles with new square-spray ABS practically-non-clogging nozzles.

- Replace slat-type drift eliminators with high-efficiency, low-pressure-drop, self-extinguishing, PVC cellular units.

- If possible, follow cooling tower manufacturer's recommended clearances around cooling towers and relocate or modify structures, signs, fences, dumpsters, etc. that interfere with air intake or exhaust.

- Optimize cooling tower fan blade angle on a seasonal and/or load basis.

- Correct excessive and/or uneven fan blade tip clearance and poor fan balance.

- Use a velocity pressure recovery fan ring.

- Divert clean air-conditioned building exhaust to the cooling tower during hot weather.

- Re-line leaking cooling tower cold water basins.

- Check water overflow pipes for proper operating level.

- Optimize chemical use.

- Consider side stream water treatment.

- Restrict flows through large loads to design values.

- Shut off loads that are not in service.

- Take blowdown water from the return water header.

- Optimize the blowdown flow rate.

- Automate blowdown to minimize it.

- Send blowdown to other uses (Remember, the blowdown does not have to be removed at the cooling tower. It can be removed anywhere in the piping system.)

- Implement a cooling tower winterization plan to minimize ice build-up.

- Install interlocks to prevent fan operation when there is no water flow.

- Establish a cooling tower efficiency-maintenance program. Start with a cooling tower energy efficiency monitoring, analyse and then make a cooling tower maintenance program a part of your continuous energy management program.

Few Important Concepts of a Cooling Tower System:

Before implementing the above-mentioned ideas to improve cooling tower efficiency, it is even important to understand a few basic concepts like cooling tower energy efficiency assessment method, cooling tower blowdown rates, and control strategies too.

Cooling Tower Blowdown:

Since cooling tower system works on the principle of evaporation, the concentration of salts in the water rises at frequent intervals of time. This increase in concentration level will decrease the heat transfer rate in the cooling tower. Hence it is recommended to blowdown or remove water from the cooling tower sump frequently. Even high blowdown rate causes wastage of water which is also not recommended. And the cooling tower blowdown rate can be estimated with the help of evaporation loss and cycles of concentration

Evaporation Loss:

Water quantity (m3/hr) evaporated from the cooling tower for cooling duty

= theoretically, 1.8 m3 for every 10,000,000 kCal heat rejected

= 0.00085 x 1.8 x circulation rate (m3/hr) x (T1-T2)

T1-T2 = Temp. difference between inlet and outlet water

Cycles of Concentration (COC):

The ratio of dissolved solids in circulating water to the dissolved solids in make up water

Blowdown Quantity = Evaporation Loss / (C.O.C. – 1)

Cooling Tower Efficiency:

The efficiency of a cooling tower is expressed in terms of effectiveness. Effectiveness of a cooling tower is defined as the ratio of Range to that of Range + Approach.

Effectiveness in % = Range / (Range + Approach)

= 100 x (CW temp – CW out temp) / (CW in temp – Wet bulb temp)

Cooling Tower Control Strategy:

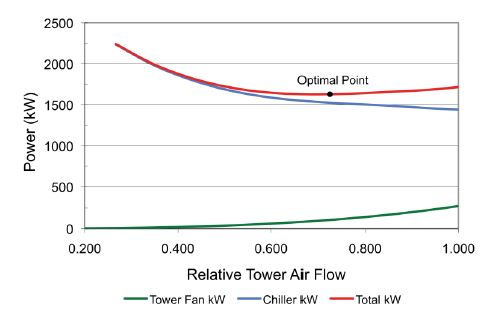

Cooling tower controls provide condenser water at the correct temperature to the chillers. Defining the correct water temperature is very important. Lowering the condenser supply water temperature increases the effort by the cooling tower resulting in more fan work, however, this improves the performance of the chiller by offering condenser relief. This chart shows how the power is affected by reduced tower airflow (higher ECWT) on the power requirement of an electric centrifugal chiller at full load.

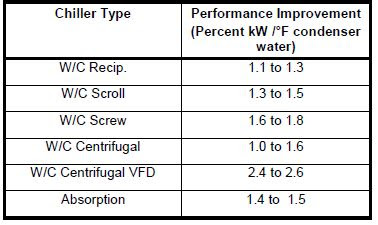

Below Table shows the range of chiller improvement that can be expected by lowering the condenser water supply temperature. The goal of cooling tower control is to find the balance point that provides the required cooling with the least use of power by the chiller plant.

Cooling Tower Control Method :

A method to control either a single cell or multiple cell cooling towers serving multiple chillers is to base the condenser supply water temperature on ambient wet-bulb. For this method, set the condenser water setpoint at the current ambient wet-bulb plus the design approach temperature for the cooling tower. The set-point will change as the ambient wet bulb

changes as seen in the below figure. Limit the setpoint between the design condenser water temperature (typically 85°F) and the minimum condenser water temperature (typically 65°F). The wet-bulb method will provide good condenser relief for the chiller and cooling tower fan work relief when the chiller is not operating at 100% capacity. This can be a good balance between chiller and tower work.

Very useful document.

ReplyDeleteThanks

Very informative. Any similar information available for energy efficient distribution transformers upto 5 MVA, please confirm.

ReplyDeletesure will update by today evening. Please check this space for more science and tech information

DeleteWe are a frp cooling towers blade manufacturer if you wants to buy any size of frp blade please contact as 8109616108

DeleteUse heigh efficiency FRP fans .

ReplyDeleteBalarka FRP fans gives 85% efficiency.

This comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeleteWe are having manufacturing facility for Power saving fan Blade assembly in aerodynamic design concepts.

ReplyDelete[email protected]

Nice information.

ReplyDeleteYou can combine all 7 of your fan suggestions into one, by retrofitting to an EC direct drive fan. (Full disclosure, I work for ebmpapst). Our fans come with full speed control, highly efficient factory balanced blades, and more. https://vac.ebmpapst.com/de/en/vac/applications/commercial-industrial-buildings/coolingtowers.html

ReplyDeleteGreat !!

DeleteCan you please let us know the typical ROI for replacing an existing belt driven IE2 class motor equipped fan with your EC fan ?

In the event that you remain on the ground and practice Yoga, Judo or Qigong, you can attract energy from the earth and store that energy in your body. www.besteenergieleverancier.com

ReplyDeleteThey were before long supplanted by another sort of synthetic, the licensed substance called Freon. Airconditioning

ReplyDeleteI have bought a few homes in similar areas because of showcasing along these lines. condos for sale in brentwood los angeles

ReplyDeleteThanks for your post. It's very helpful post for us. You can also visit Attic Insulation Companies for more Victor Steel related information. I would like to thanks for sharing this article here.

ReplyDeleteThe water moves through spouts, showering water into the material called "fill," which eases back the progression of water through the cooling pinnacle, and uncovered however much water surface as could reasonably be expected for greatest air-water contact. Beyond Heating And Cooling

ReplyDeleteWhenever the water and air meet, a modest quantity of water is vanished, making a cooling activity.Aircon Servicing

ReplyDeleteVarious organizations offer different supporting offers and for certain clients this can be the game changer in which organization they decide to work with. Most clients are searching for an organization that offers some sort of regularly scheduled installment plan with low-loan fees.

ReplyDeletegas ducted heating cost

This implies venting the exhaust hose with a venting unit. This typically comes included with the versatile air conditioner when it is bought and can be slid into a window. heat

ReplyDelete"I'm grateful for the air conditioner in my favorite restaurant, as it enhances the overall dining experience." hvac

ReplyDeletePros and cons of gas vs. electric water heaters – which is better? water heater replacement plano tx

ReplyDeleteWater heater maintenance should be on every homeowner's to-do list. water heater replacement nm

ReplyDeleteRegularly clean or replace air filters for better air quality. water heaters in berkeley ca

ReplyDeleteAir conditioning systems with variable-capacity compressors provide precise temperature control.

ReplyDeleteair conditioning contractor Rockhampton